Decontamination pass-through cabin is most frequently used as material pass-through to transfer material between rooms with different classes of cleanliness (typically B and C). Equipment and materials are decontaminated in a decontamination cycle using hydrogen peroxide vapour. Hydrogen peroxide vapour generator is part of the pass-through decontamination cabin; the two form a single piece of equipment.

DEVICE DESCRIPTION

- Integrated VHP generator

- Mobile perforated shelves allow sterilization of the product from all sides

- Process works at normal temperatures (at about 25 - 30 °C) and normal pressures

- HEPA H 14 filtration in the inlet as well as the outlet of the pass-through cabin

- Material of pass-through chambers – AISI 316L (EN 1.4404), polished surface finish with rounded corners

- Other construction materials – AISI 304, hardened glass, silicone, POM-C, etc.

- Compressed air of pharmaceutical quality is required

- Possible validation of decontamination cycle

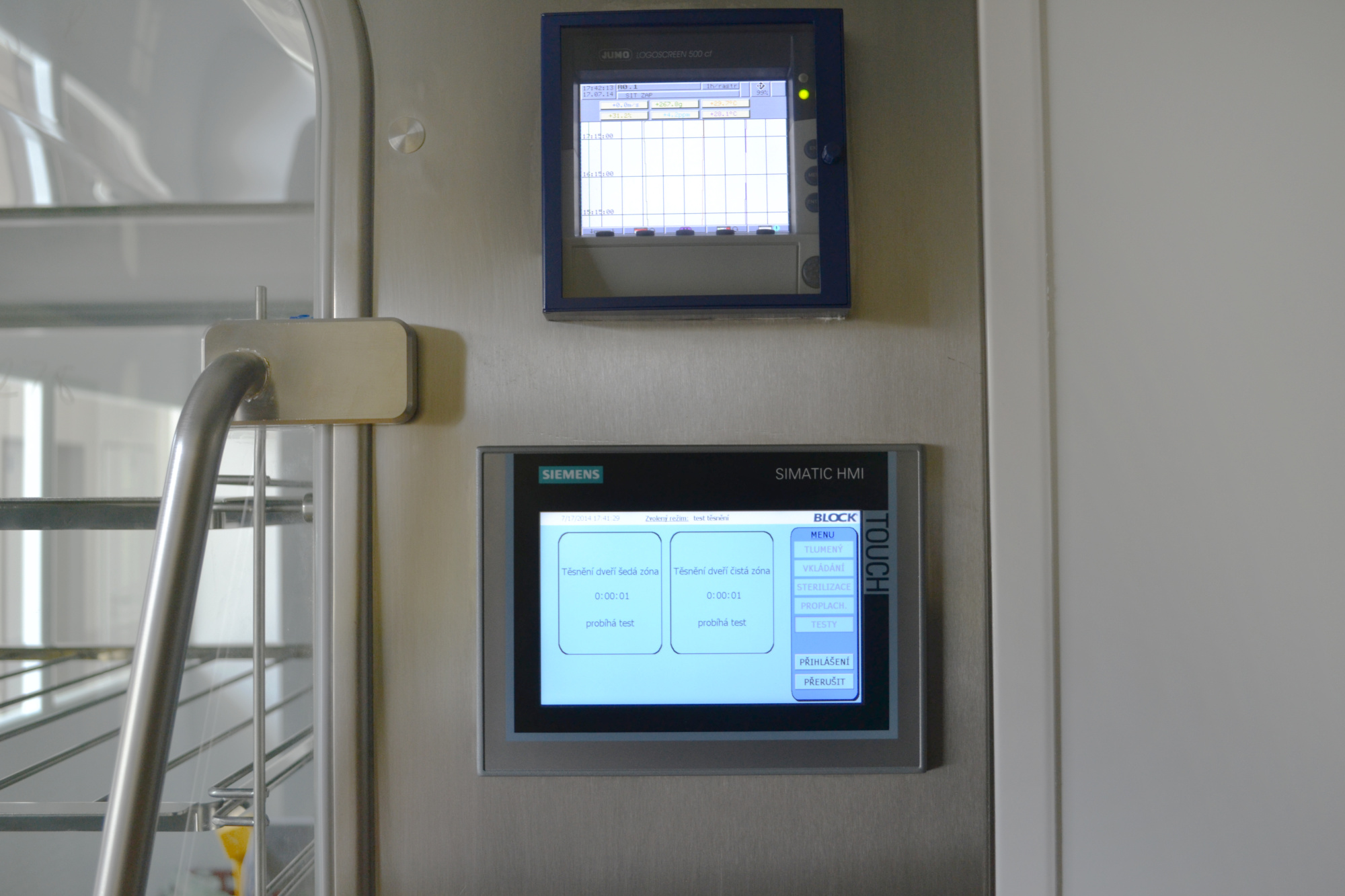

- Possible data recording on a recording unit, printer or PC

ADVANTAGES

- Cabin complies with the leak tightness classes pursuant to ISO 10648-2.

- Low operating costs

- Low-temperature decontamination

- Quick interval of a decontamination cycle

- Environmental protection, by-products are only water vapour and oxygen

- Long operation life, minimal maintenance demands

- Choice of several types and sizes

- Easy handling and operation