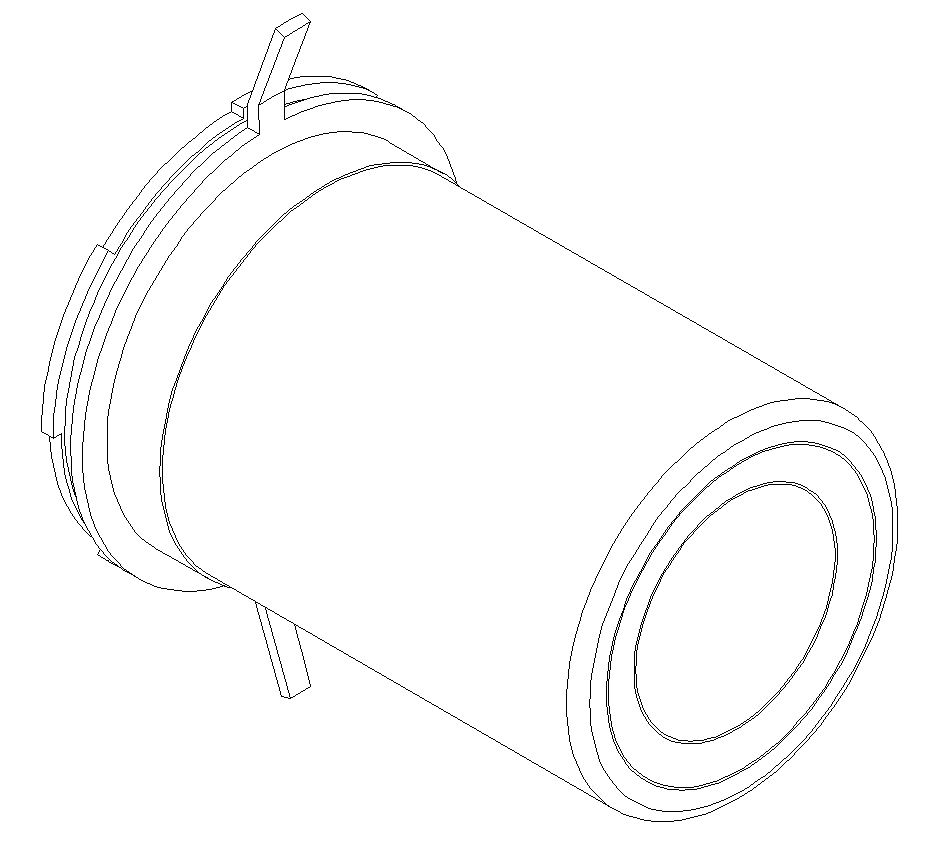

RTP (Rapid Transfer Port) is a device used to safe transfer material from the chamber to another location, while preventing contamination of the product or the environment. RTP consists of two basic parts. The Alpha port is fixed on the isolator chamber; the Beta port, which is connected to the Alpha port, is used as a container for material transfer. RTP is based on a double-door principle; the port into the container may not be opened until the Alpha and Beta ports are connected. RTP is often used for material output and transport or for the removal of solid waste from the chambers. The system is available in four standard sizes: 105, 190, 270 and 350 mm. Beta ports are available in two material versions: PE and stainless steel. The materials are resistant to multiple sterilization (autoclave, ethylene oxide, gamma sterilization, H2O2 sterilization, etc.).

The RTP system features the following safety systems to protect against accidental detachment:

- The Alpha door cannot be opened if the Beta container is incorrectly connected or placed.

- When the Alpha door is opened, the Beta container cannot be disconnected.

| Selection of dimension range and material design |

|---|

| dimension range 105, length 400, stainless steel design |

| dimension range 190, length 400, stainless steel design |

| dimension range 270, length 400, stainless steel design |

| dimension range 350, length 500, stainless steel design |

| dimension range 190, length 400, polyethylene design |

| dimension range 270, length 400, polyethylene design |

| dimension range 270, length 500, polyethylene design |

| dimension range 350, length 500, polyethylene design |

| In this category, you can select the size of the Beta containers and their material design. |